When you visit any website, it may store or retrieve information on your browser, mostly in the form of cookies. This information might be about you, your preferences or your device and is mostly used to make the site work as you expect it to. The information does not usually directly identify you, but it can give you a more personalized web experience.

Because we respect your right to privacy, you can choose not to allow some types of cookies. However, blocking some types of cookies may impact your experience of the site and the services we are able to offer.

You Allow:

Strictly Necessary Cookies(Required)

These cookies are necessary for you to browse our website and use its fundamental services,and they don't require your consent.These cookies allow us to offer you the essential functions of the website(account access,language used,order played,payment etc),and can also be used for identity verification and security.If you disable them,we will not able to fulfill your basic request.

These cookies collect anonymous information on your online operation behaviors that help us improve website construction. If you reject these cookies, you may not be able to use certain features of our websites and services.

These cookies allow us to remember the choices you have made about your preferences, such as what language you prefer. If you reject these cookies, you may feel that the efficiency of browsing the web has decreased.

These cookies carry out personalized activities to advertise products and services which you are interested. If you reject these cookies, you will still see advertisements that are not much relevant to your interest or demand.

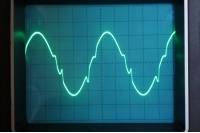

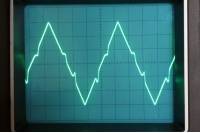

Hanks Two FG-100 DDS Generators were purchased. One had distorted waveforms, even worse than shown above, at over 1KHz while the 2nd. had clean waveforms right up to 100KHz. I compared the 2 PCB assemblies and you can see that the good one had been resoldered after manufacture. The design of this unit is excellent, the manufacture looks good, but when tested, it is obvious that the SMT assembly temperature was too low or the belt moved too fast thru the flow oven. This is typical of the ROHS no-lead solder that requires higher heat to solder than the lead-based solder. So the solder looks good but it has not adhered to the solder pads of the components. By simply resoldering the parts manually on the top of the PCB assembly, everything works OK. I am referring only to the 2 Op-Amps (LM358 or TL022) and resistor/capacitor parts on the output stage. With both the good and bad DDS, the outputs of the microcontroller chip thru the resistor networks, were excellent waveforms. If you want to see photos, contact: us@soundeffx.com